Increased

Downtime

Response

Time Loss

Each Bottleneck

Cost

Productivity

Drop

Unplanned

Downtime

Disruptive

Production

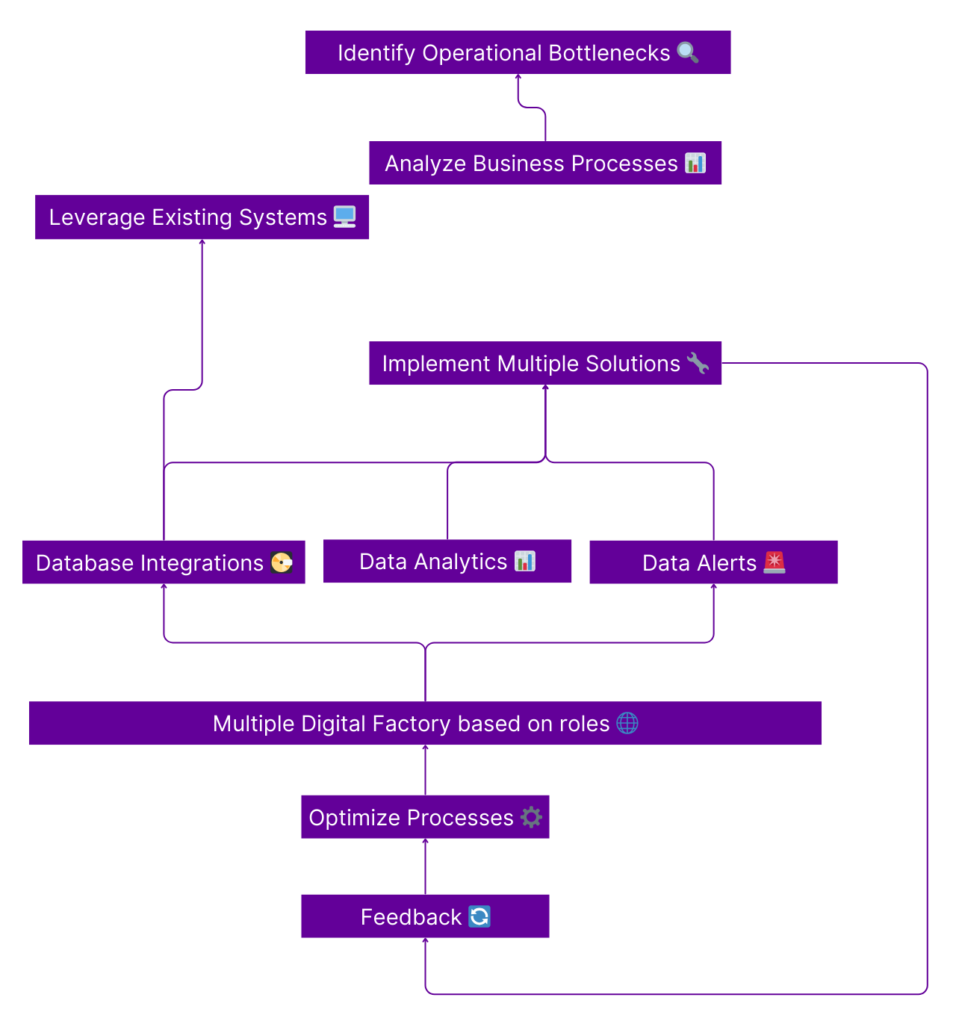

We bring you a superpower that helps your businesses make smart decisions and grow

Our twin software ensures that your data stays with you, providing a secure, private, and reliable solution

Our twin software offers cost-effective solutions, delivering high-quality performance without compromising on affordability or security.

It ensures faster implementation, enabling you to quickly integrate and benefit from advanced solutions with minimal downtime

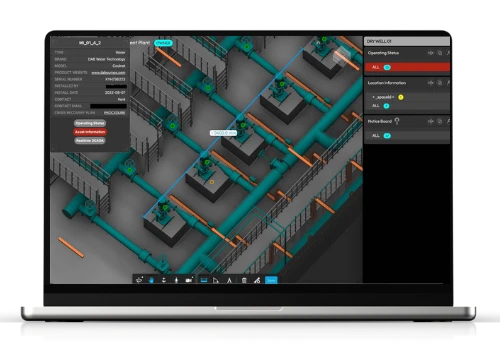

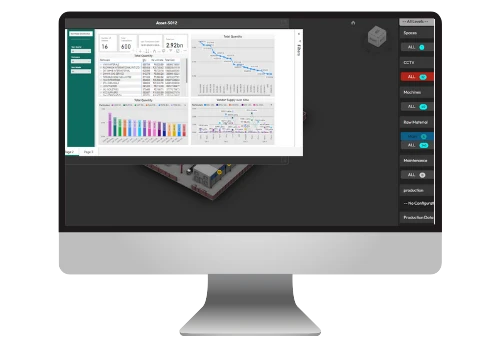

Seamlessly view and manage all your data, processes, and assets in one place for streamlined efficiency and smarter decision-making

Instantly access live sensor readings for real time monitoring and swift response, enhancing operational efficiency and decision-making.

Instantly access live sensor readings for real time monitoring and swift response, enhancing operational efficiency and decision-making.

Instantly access live sensor readings for real time monitoring and swift response, enhancing operational efficiency and decision-making.

Instantly access live sensor readings for real time monitoring and swift response, enhancing operational efficiency and decision-making.

Digital twin technology can be utilized by various types of factories across different industries

Digital twin technology can be utilized by various types of factories across different industries

By 2025, 463 exabytes of data will be created each day globally, which is equivalent to over 200 million DVDs of data per day (Source: World Economic Forum). This data explosion demands advanced tools to harness and analyze it effectively for actionable insights.

General Electric (GE) reported saving $1.5 billion in maintenance costs across its fleet by using digital twin technology to predict failures and optimize maintenance schedules (Source: GE Reports). This illustrates the substantial financial benefits of adopting digital twins.

Digital twins enable hyper-personalization and increased efficiency in various sectors. For instance, in manufacturing, digital twins can increase production efficiency by up to 25%. (Source: L &T)

Industry 4.0, characterized by the fusion of digital, physical, and biological worlds, is driving the adoption of digital twins. Over 40% of large industrial companies will use digital twins by 2027, leading to a 10% improvement in effectiveness. (Source: Science Direct)

Digital twins play a vital role in achieving sustainability goals. They help optimize resource usage and reduce waste, contributing to a greener planet. For example, Unilever’s digital twin initiatives have reduced its energy consumption by 15% and water usage by 20% in its factories.

The digital twin market is expected to grow from $3.1 billion in 2020 to $48.2 billion by 2026, at a CAGR of 58%. This rapid growth highlights the increasing demand and potential for digital twin technology across various industries. (Source: McKinsey)

By 2025, 463 exabytes of data will be created each day globally, which is equivalent to over 200 million DVDs of data per day (Source: World Economic Forum). This data explosion demands advanced tools to harness and analyze it effectively for actionable insights.

General Electric (GE) reported saving $1.5 billion in maintenance costs across its fleet by using digital twin technology to predict failures and optimize maintenance schedules (Source: GE Reports). This illustrates the substantial financial benefits of adopting digital twins.

Digital twins enable hyper-personalization and increased efficiency in various sectors. For instance, in manufacturing, digital twins can increase production efficiency by up to 25%. (Source: L &T)

Industry 4.0, characterized by the fusion of digital, physical, and biological worlds, is driving the adoption of digital twins. Over 40% of large industrial companies will use digital twins by 2027, leading to a 10% improvement in effectiveness. (Source: Science Direct)

Digital twins play a vital role in achieving sustainability goals. They help optimize resource usage and reduce waste, contributing to a greener planet. For example, Unilever’s digital twin initiatives have reduced its energy consumption by 15% and water usage by 20% in its factories.

The digital twin market is expected to grow from $3.1 billion in 2020 to $48.2 billion by 2026, at a CAGR of 58%. This rapid growth highlights the increasing demand and potential for digital twin technology across various industries. (Source: McKinsey)

Unutilized

Up to 65% of generated data goes unutilized in manufacturing, representing missed opportunities for efficiency and innovationData